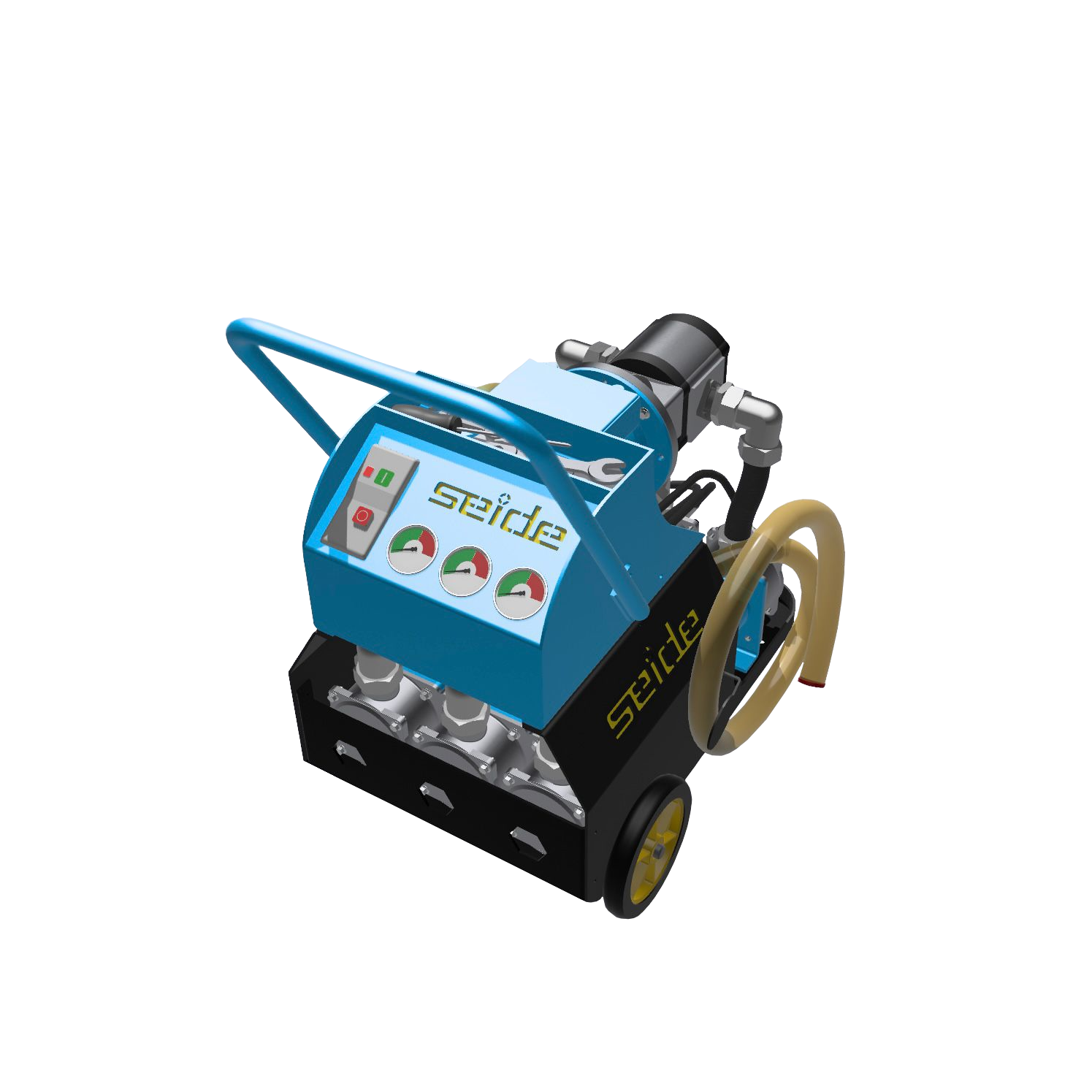

Seide RK91 Mobile Filtration and Flushing Machine | Uninterrupted Cleaning and Reliable Performance for Hydraulic Systems

In today's industrial facilities, hydraulic systems are the most critical part of production. Up to 80% of failures in these systems are caused by hydraulic oil contamination — making accurate filtration and oil cleaning solutions critical. This is where the Seide RK91 Mobile Filtration and Flushing Machine revolutionizes hydraulic maintenance processes. Offered with the assurance of Hidroman, RK91 is not only cleaning but also a real protective tool that extends the life of the system. hidroman.com.tr+1

Why RK91 in Hydraulic Filtration

Contaminants in hydraulic systems are made up of very small particles — even particles of 10 microns and below can cause serious system failures. The RK91 is a mobile filtration and flushing unit designed to solve this problem. While the flushing process rotates inside the system you lubricate and mechanically removes sediment and dirt; Filtration captures and expels these impurities at the micron level. hidroman.com.tr

Important Point

The vast majority of hydraulic failures are caused by oil contamination.

RK91 effectively eliminates this contamination, extending the life of the device. hidroman.com.tr

Technical Specifications — Maximum Performance with RK91

|

Feature |

Value |

|

Pump Flow Rate |

80 L/min |

|

Number of Filters |

3 Stage |

|

Filter Permeability |

950 L/min each stage |

|

Filter Dirt Holding Capacity |

900 g (each filter) |

|

Filter Sensitivities |

60, 25, 10 micron (5 micron optional) |

|

Engine Options |

230 VAC single-phase or 400 VAC three-phase |

|

ISO / NAS Cleanliness Level |

Up to NAS5 level |

|

Particle Measurement Capability |

2–100 micron measurement |

|

Compact & Mobile Design |

Yes |

|

Compatible with Pollution Meter |

Yes, reporting can be done with an electronic particle counter |

Thanks to these technical details, the RK91 provides both high-flow filtration and high-precision particle control. Especially as the last stage, the 5-micron filtration option makes a difference in protecting sensitive components. hidroman.com.tr+1

Filtration Performance

The multi-stage filtration process of RK91 targets particles of different sizes present in hydraulic oil:

60 micron filter – Captures large contaminants in the first place.

25 micron filter – Removes medium-sized particles.

10-micron filter – Captures small particles that can damage sensitive components.

5 micron (Optional final stage) – Provides ultra-fine cleaning. hidroman.com.tr

This structure increases the operating life of the hydraulic system, extends maintenance intervals and significantly reduces unplanned downtime.

Why Choose RK91?

Efficiency and Economical Use

The high filtration capacity of RK91 ensures that the filter lasts longer and requires fewer replacements. This translates to savings of up to 400% in maintenance costs. hidroman.com.tr

Compact and Mobile Design

The chassis and lines have a lightweight and portable structure with a monolithic design. In this way, it can be easily used in both field and workshop applications. hidroman.com.tr

Precise and Reportable Result

Thanks to the electronic particle counter that can be integrated into the device, system cleanliness can be measured and reported in real time — which strengthens preventive maintenance strategies. hidroman.com.tr

What is the Filtration and Flushing Process?

Filtration: It passes through the hydraulic oil and removes particles at the micron level.

Flushing: Mechanically removes sediment and dirt by circulating through the system.

The RK91 is a mobile and powerful unit that can do both of these things together — so that the oil is constantly cleaned and clean oil circulates through the system. hidroman.com.tr

Application Areas

The Seide RK91 provides significant advantages in the following areas:

Industrial hydraulic systems

Mobile hydraulic systems

Test benches

Press and machine lines

Power units

Maintenance service vehicles

In every industry, hydraulic cleaning directly affects system life and safety; With the RK91, this critical requirement is met.

Smart Filtration for Your Hydraulic Systems

The Seide RK91 is a mobile filtration and flushing machine that ensures reliable, powerful and measurable cleanliness in hydraulic systems. With features such as ISO/NAS standards-compliant results, high flow rate and compact construction, this machine offers much more than conventional filtration solutions.

For facilities looking to extend system life, reduce the risk of failure, and lower maintenance costs, the RK91 should be the go-to choice.

Questions and Answers from Our Customers (Clear and Honest Answers)

"I already have a filter in my system. Why is RK91 necessary?"

Existing system filters only keep the momentary contamination at the time of operation.

But:

Initial commissioning

Overhaul and part replacement

Addition of oil

Hose and equipment assembly

They cannot hold the high pollution load that occurs at such moments.

The RK91 works independently of the system, turning the oil over and over again and reducing it to a level of cleanliness that a fixed filter can never reach.

Fixed filter runs system

RK91 protects system

"My machine is running smoothly, why should I buy it now?"

The most expensive breakdowns in hydraulic systems:

No advance warning

Causes sudden downtime

Locks production

70–80% of these failures are caused by oil contamination.

RK91 is not a repair machine, but

a fuse that activates before a malfunction occurs.

Expenditure after the breakdown = compulsory expenseRK91 investment = controlled and planned profit

"My oil is new, do I need filtration?"

Yes. Because the new oil:

Barrel and gets dirty during transfer

Contains particulates above ISO/NAS standards

As soon as it enters the system, it starts to damage the valve and pump surfaces

Oil with RK91:

Before entering the system

Or it

is reduced to actual working cleaning within the system.

New oil is not clean oil. The Oil Through RK91 Filtration Machine is safe and clean oil.

"Isn't this investment expensive?"

The most expensive thing is:

1-day unplanned downtime

Servo valve failure

Pump overhaul

Emergency service and loss of production

RK91:

Extends oil life

Reduces filter replacement

Increases part life

Reduces the risk of failure

In most plants, a single prevented failure greatly reimburses the cost of the RK91.

The question should be:

"What does it cost me not to do filtration?"

"We have worked without filtration until today, why now?"

Because:

Hydraulic tolerances have shrunk

Servo and proportional valves have become widespread

Pressures and performance expectations increased

Pollution, which used to be tolerated, is today a direct cause of failure.

The RK91 brings your existing system

to today's cleanliness standards.

"Does mobile filtration really make a difference?"

Yes. And measurably.

RK91:

Measures particles between 2–100 microns

Clearly shows the level of ISO/NAS cleanliness

Ends the "Is it clean?" debate

Data-driven maintenance, not guessworkWith maintenance, you're in control

"Who is the right choice for RK91?"

If:

If production downtime is a risk for you

If you are using servo/precision valves

If you want to extend the power unit life

If you want to see maintenance as an investment, not a cost

RK91 is made for you.

Last Question:

"Is It Riskier To Buy Or Not To Buy?"

RK91:

Won't stop your system

It does not put your production at risk

Works without malfunctioning

But a hydraulic system without filtration

will sooner or later stop.

RK91 wins before failure happens, not after