Large Hydraulic Cylinders: Special Solutions

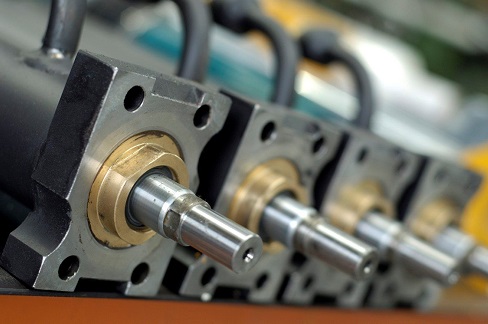

Your project is our duty in Hidroman. We custom design and manufacture cylinders, high pressure reciprocating accumulators and pressure systems for your specific applications. In the manufacture of our large hydraulic cylinders, the diameter can be between 200 mm and 1.500 mm and the stroke length can be up to 24.000 mm. Our expert engineers have a lot of experience and knowledge for various industry sectors and know the specific requirements of your application.

Hidroman has serious knowledge and experience in large hydraulic cylinder manufacturing and revision. Our application-based engineering and manufacturing processes in line with world standards ensure that each cylinder is perfectly built and fit for its task. Safe and reliable processes are essential for all industries using these large cylinders. One of the most important parts of large hydraulic cylinders is the piston rod surface. Hidroman has many studies in developing new technologies that improve uptime and reduce total cost.

Apart from Hidroman, special sizes and special surface technologies, we also offer additional services in the table below. In addition to cylinders, we also offer integrated measuring systems as well as perfectly compatible power units, hydraulic pipelines and control systems / solutions services.

Additional services such as project management, engineering, commissioning, supervision and training are already provided within the scope of cylinder manufacturing / revision within the body of Hidroman. Production, as the main contractor throughout Turkey with sales and service network in the domestic service area; and / or solution

As a partner, we are with you all cylinder manufacturing / revision. Hydroman's large hydraulic cylinders always fit your machine perfectly!

Large Hydraulic Cylinder Manufacturing

Hydraulic Cylinder Engineering and innovations

Hydraulic Cylinder Shaft Surface technologies

Marine Applications in Hydraulic Cylinder

Offshore applications in Hydraulic Cylinder

Civil engineering applications in Hydraulic Cylinder

General industrial applications and presses in hydraulic cylinders

Steel Factory and rolling mill application in hydraulic cylinder

Bulk Material Handling Apparatus in Hydraulic Cylinder

Construction and Construction Machinery Hydraulic Cylinder Manufacturing

Agricultural Machinery Hydraulic Cylinder Manufacturing

Hydraulic Cylinder Manufacturing in Mining Applications

Engineering and Manufacturing: Using Real Performance Potential

Often large hydraulic cylinders are used to transmit heavy forces in harsh environments. In addition, they must operate reliably and safely over a long period of time. Only systematic engineering and manufacturing processes can ensure that the cylinder always meets the needed requirements. Hidroman has developed specific design tools and in-house research facilities for a reliable and cost-effective cylinder design.

Preventing Deflection and Bending in Hydraulic Cylinders

Our experts calculate the deflection and bending of the hydraulic cylinders. Friction moments, transverse loads, accelerations and eccentric loads in spherical bearings are taken into account in all mounting types. The calculations also include typical events such as manufacturing clearances in the roller guide and defining the bearing material. The result is an accurate assessment for the cylinder under push and tensile loads. The position of the spindle head and the spindle inside the cylinder are analyzed in detail. The stresses in the piston, cylinder and bearings are precisely calculated. In these cases inside the cylinder, a force stroke diagram is required.

Prevention of Metal Fatigue in Hydraulic Cylinders

In addition to the applicable standards, Hidroman has developed a series of test processes for materials under the guidance of our expert engineers. In these processes, details are calculated and combined with calculation methods according to recognized standards to achieve a reliable design without critical fatigue. Calculations cover parameters such as material type, thickness, local stresses, amplitudes, stress gradients, and number of load cycles. A load spectrum is required for the cylinders in dynamic test applications.

Hydraulic Cylinder Surface Technologies:

Improve uptime while lowering your total cost In large hydraulic cylinders, the shaft surface is one of the most important parts of hydraulic installation. The right combination of surface technology, sealing and hydraulic media determines the final running time of the cylinder and the total cost. Hidroman has always been a solution partner in the development of various in-house technologies for every industry and application.

Best Surface Technology in Hydraulic Cylinder

Hidroman uses an application integrated with all systems to select, design and manufacture the best surface technology in any industry or application. It combines all surface technologies for the shaft surface. To develop this concept, we have well-prepared all sample surface technology data in the world.

analyzed and applied.

Other Solutions

Hidroman can also supply chrome plated shafts in applications that are proven to provide the best combination of functionality, functionality, durability and total cost.

Proper Gasket / Seal Use

Hidroman has developed a gasket configuration for all kinds of applications and shaft surfaces. This structuring is the result of a program to analyze and experience the world's leading gasket manufacturers data well. Analyzes the friction, lubrication and wear of interacting surfaces in motion. It is suitable for speeds up to 15 m / s, can be used for low friction applications and has excellent wear properties.

Cylinder Usage / Maintenance Time: Improving Overall Equipment Effectiveness

More than 90% of cylinder use / maintenance costs are determined at the design stage. Hydroman, which is already in all engineering stages of manufacturing, can save you maintenance time and costs, as well as increase availability throughout the life of the cylinder.

Hydraulic System Improvements

Hidroman has developed important manufacturing details and cylinder shaft technologies that offer two-sided advantages: In addition to a longer life, Hidroman cylinders save maintenance time and increase the operating time and profitability of the systems.

Hydraulic Cylinder Maintenance / Repair

Hidroman offers various maintenance and repair services. Our maintenance concept consists of spare parts manufacturing / management and delivery, field service, regular system checks, repair / revision services and system technology upgrades. Turkey to support your maintenance operations

We cooperate with various specialist service centers around the world.

As Hidroman, the main purpose is to be the best solution partner to all our customers and to offer all our services in the best way.