What is a Hydraulic Oil Tank?

Hydraulic oil tank is a tank or tank where hydraulic oil is stored in hydraulic systems. Hydraulic systems are systems that perform mechanical movement using fluid power. In these systems, hydraulic oil is transferred under pressure through pipelines or hoses and enables the movement of pistons in components such as hydraulic cylinders or motors.

The hydraulic oil tank provides a place to store hydraulic oil and keeps the oil level in the system constant. It may also have an air gap or air bubble to allow airflow into the system and facilitate circulation of hydraulic oil.

Hydraulic oil tanks are generally made of metal (mostly steel or aluminum) or plastic materials. These are generally designed to be compatible with other components in the system and have properties such as tightness, pressure resistance and corrosion resistance.

Hydraulic oil tanks generally work together with other components in the system to ensure that hydraulic systems operate efficiently and reliably.

Hydraulic Oil Tank Types

Hydraulic oil tanks come in a variety of types to suit different application requirements and system designs. Here are some commonly used hydraulic oil tank types:

Rectangular Tanks: One of the most common types of hydraulic oil tanks. Rectangular tanks are usually installed in a horizontal position and have a wide base, increasing stability and being able to store more hydraulic oil.

Circular Tanks: These tanks have a circular shape and are usually designed to take up less space. Circular tanks are preferred in some applications where they must be installed in limited spaces.

Low Profile Tanks: These tanks are generally designed for shallow underground installations. They offer a low profile to take up less space at the bottom of the system or under vehicles.

High Capacity Tanks: Used to store large amounts of hydraulic oil required for large hydraulic systems. These tanks are ideal for high flow systems or applications requiring long run times.

Air Regulated Tanks: Some tanks are designed to adjust air pressure to regulate the level of hydraulic oil inside. This can be used to optimize the performance of the hydraulic system.

Stainless Steel Tanks: Especially designed for use in environments subject to corrosion. Stainless steel tanks ensure durability and long life.

These tanks may often have special mounting fixtures or mounting features, and features such as sealing, compressive strength, and air gap are designed to fit system requirements.

Hydraulic Oil Tank is generally known as a neglected equipment in the hydraulic system. However, hydraulic oil tank is an important system part as other hydraulic equipment. The following equipment should be used in hydraulic oil tank production.

How to Manufacture Hydraulic Oil Tank

Hydraulic oil tank manufacturing must be carried out in accordance with certain engineering standards and safety guidelines. Here are the basic steps for hydraulic oil tank manufacturing:

Design Phase:

Requirements such as dimensions, shape and capacity of the tank to be manufactured must be determined.

The design must comply with the requirements of the system and application in which the hydraulic oil tank will be installed.

Material selection must be made. Suitable materials such as steel, aluminum or plastic can be preferred.

Material Preparation:

The materials required for the manufacture of the tank must be provided.

Materials must be cut, shaped and prepared in accordance with the design.

Welding or Assembly Process:

For metal tanks, parts are usually joined together by welding or joining.

For plastic tanks, thermal or chemical bonding techniques can be used.

The parts are brought together and assembled to create the structure of the tank.

Sealing and Testing Procedures:

The tightness of the tank should be checked. This can be accomplished by pressure tests or tightness tests.

The tank must be equipped with seals or gasket materials to prevent leakage of hydraulic oil.

Adding Accessories:

Necessary accessories should be mounted on the tank. This may include parts such as air gap, fill inlet, level indicator, pressure relief valve.

Parts such as doors, hinges, locks or locking mechanisms must be added.

Painting or Coating:

The outer surface of the tank should be subjected to a suitable coating or painting process to prevent corrosion and provide an aesthetic appearance.

Quality Control and Approval:

The quality of the manufactured tank should be checked for suitability and reliability.

Compliance with the necessary standards and requirements of the directives must be ensured.

Manufacturing hydraulic oil tanks is a delicate process that requires engineering knowledge and experience. Therefore, it is recommended to be done by professional manufacturing enterprises or specialized engineering firms.

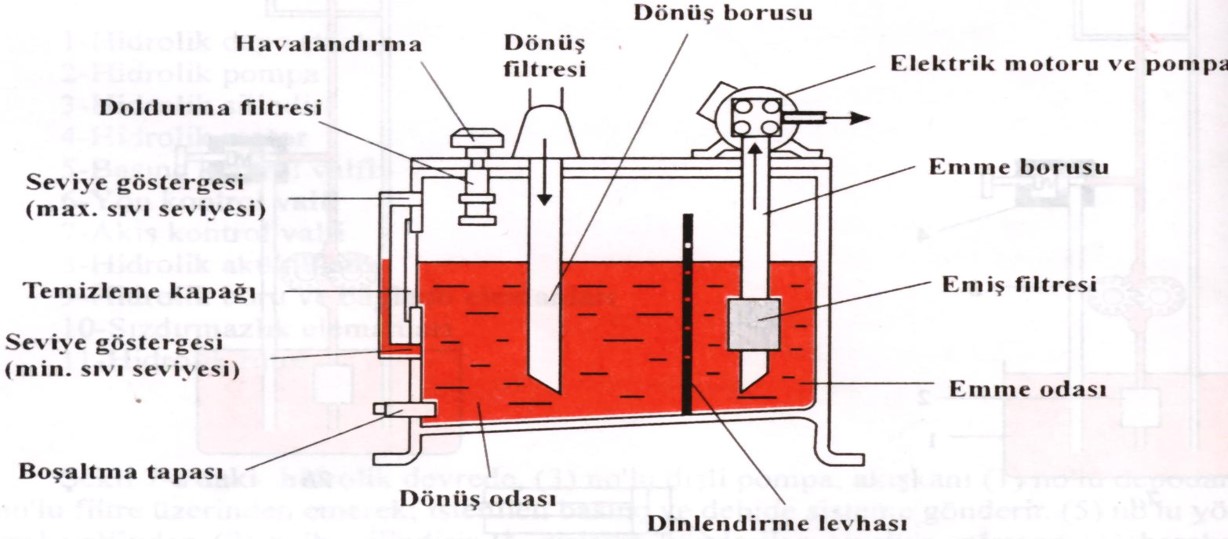

The oil is filled into the tank through the strainer (b-c) of the filler cap. The air filter (b) supplies fresh air to the tank. Level indicators (d) indicate that the oil is in the required amount. The thermometer (e) controls the oil temperature. The plug (i) provides ease in oil drainage.

The amount of oil to be filled in the tank should be enough to feed the circuit. While designing the surface area of the tank, it should be preferred that the oil should be sized to transfer the heat to the outside. Transferring excess heat in the oil of the tank in the system to the environment reduces power loss.

Description and symbol of the oil tank:

1- The tank is the element that accommodates and relaxes the hydraulic fluid.

2-While the oil is pouring into the tank, an irregular flow occurs.

3. Intermediate screen It eliminates the irregularity in the hydraulic oil.

4. Hydraulic Oil is reabsorbed by the pump.

Hydraulic Oil Tank should ensure that the fluid circulating in the system is cooled.

Hydraulic Oil Tank should ensure the separation of air, water and foreign materials in hydraulic oil.

Equipment Used in Hydraulic Oil Tank

a) Steel plate, Aluminum or plastic based Tank

b) Oil filler cap (Ventilated)

c) Oil filling Filter

d) Oil level indicators

e) Thermometer

f) Return Filter

g) Suction filter

h) Suction pipe

i) Return pipe

i) Oil drain plug

j) Intermediate curtain

k) Cleaning cover

l) Fasteners

Features of the oil tank:

1. The intermediate screen (j) acts as a breakwater for oil returning to the tank.

2. The slope at the bottom facilitates the accumulation of foreign matter. It is important for cleaning.

3. It is recommended that the ends of the pipes (h-i) are 2 times the diameter of the pipes above the bottom.

4. The curvature of the pipe ends provides ease of suction and rotation.

5.The minimum oil level should be 10 cm above the pipe end.