What is Hydraulic Connection Fitting? What are the Hydraulic Connection Fitting Thread Standards and Types?

Hydraulic fittings are parts used to join, route or convert hydraulic pipes. These fittings are used to enable the assembly of pipelines and are generally designed to operate under high pressure. In hydraulic systems, fittings have an important role in ensuring sealing and increasing the reliability of pipelines.

Hydraulic fittings are usually made of steel or alloy steel because these materials are durable under high pressure. Unions can come in many different designs and connection types, providing a variety of options to meet different application requirements. For example, there are various types of hydraulic fittings such as female and male connectors, T-connectors, elbows, transition fittings and flange fittings.

Hydraulic fittings often come with screw or clamp type connections to facilitate assembly and disassembly. Additionally, some fittings may include o-ring seals or other seals, ensuring tightness and improving system efficiency.

Hydraulic fittings should be considered as an important component when designing a hydraulic system or making modifications to an existing system. Choosing the correct fitting can affect system reliability, performance and durability. Therefore, the quality, suitability and compatibility of hydraulic fittings are of great importance.

Hydraulic Fitting Types

There are many different types of fittings used in hydraulic systems, each designed for a specific application or connection requirement. Here are some commonly used hydraulic fitting types:

1. **Female and Male Fittings:** These fittings consist of male and female parts with a threaded connection. The female fitting has an inward thread, while the male fitting has an outward thread. These fittings are commonly used to join pipelines.

2. **Elbow Fittings:** Elbow fittings are used to convert or route pipelines. They can be available at different angles, such as 90 degree or 45 degree elbows. These fittings allow pipelines to turn from one corner to another.

3. **T-Connectors:** T-connectors split or join a pipeline in three directions. These fittings are used to branch or interconnect pipelines.

4. **Duplex Fittings:** These fittings are used to join or route two pipelines. Both ends can be the same or different sizes.

5. **Transitional Unions:** Transition unions are used to combine pipelines of different diameters or different types. For example, converting an internal thread fitting to an external thread fitting.

6. **Flanged Fittings:** Flanged fittings are used to join or join pipelines with flanged connections. These fittings are commonly used in high pressure applications and the flanges are sealed with gaskets to ensure tightness.

7. **Couplings and Hose Couplings:** Couplings and hose couplings are used to connect hydraulic hoses or flexible pipes to pipelines. These types of connections are commonly used in mobile or flexible applications.

These are just a few examples, and the variety of fittings used for hydraulic systems is quite wide. Depending on application requirements, working pressure and other factors, different fitting types may be preferred.

Fasteners are spacers used for joining block inputs and lines with two and / or more outlets without direct compatibility. Fasteners can be classified into product groups depending on the configuration type.

JIC (UNF)

ORFS (Get Flat)

BSP (NPT)

Metric

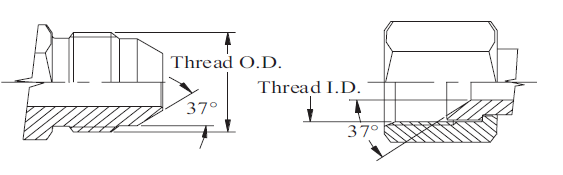

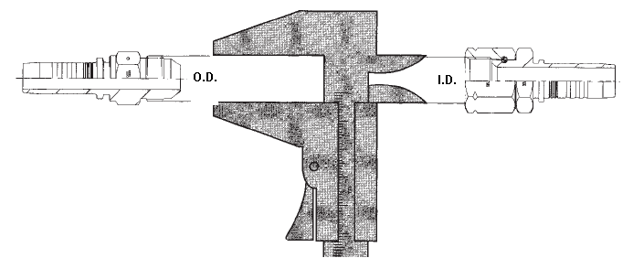

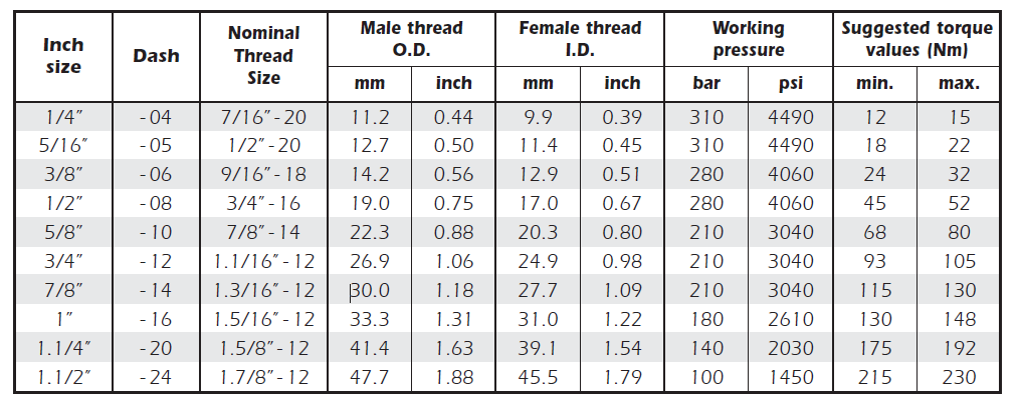

SAE J514, 37 ° FLARE - JIC (UNF Hydraulic Fitting)

This type of connection is very common in hydraulic circuits. Both male and female have 37 ° tapered seats and sealing occurs when straight threads engage. The connection is made mechanically by means of threads. This connection type is the American Standard and is widely used in America. It is widely used in pipe connections.

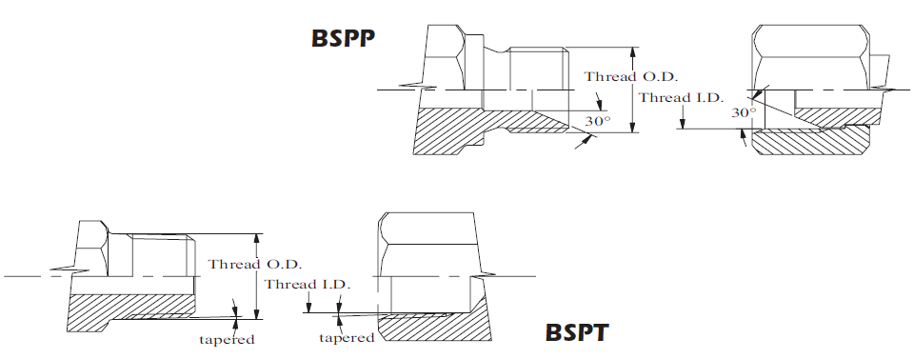

British Standard Pipe - BSP (BSPP Parallel - ISO228-PT & BSPT Tapered- ISO7-PT) BSP Hydraulic Fitting

There are two types of Standards in BSP type fittings: BSPP and BSPT

In BSPP, the thread is parallel and the male has a 30 ° tapered countersink, which sits on top of the BSPP female on a 30 ° tapered countersink. In BSPT, the male thread is conical and usually attached to a block. Sealing takes place with the thread end, so teflon tape or sealing fluid should be used during assembly. In some sizes there is a similarity between BSPP / BSPT and American connections NPSM / NPT. BSPP and BSPT British Standard are widely used in the UK.

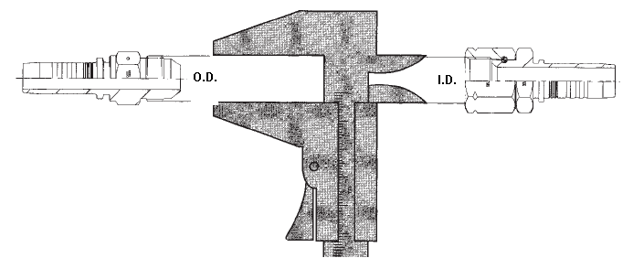

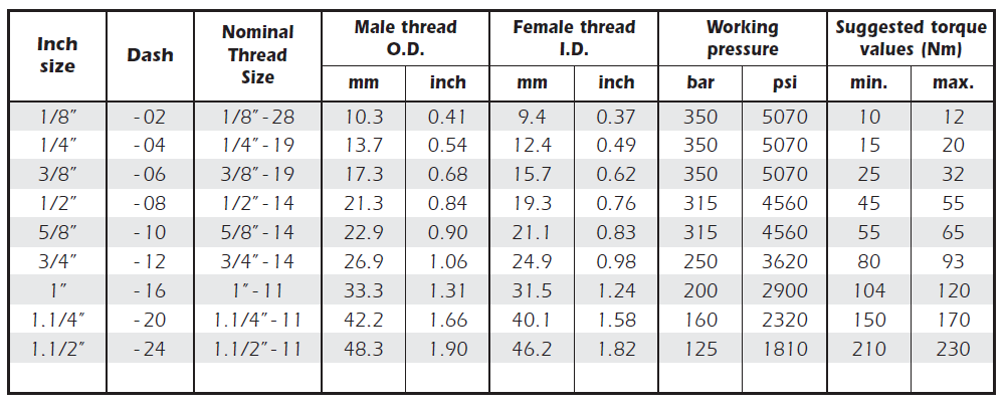

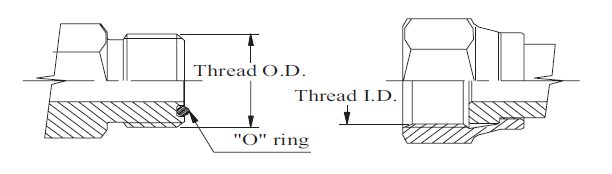

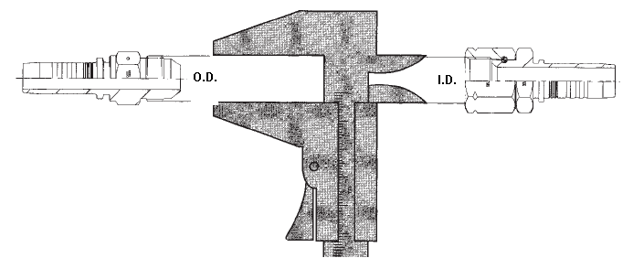

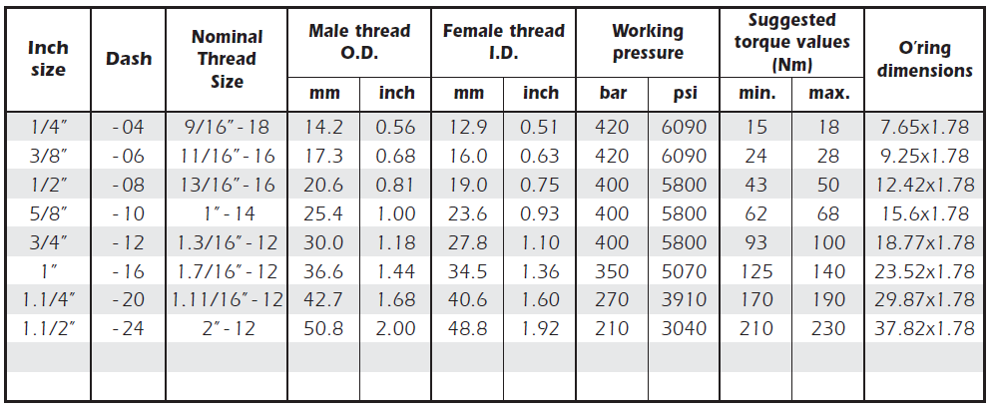

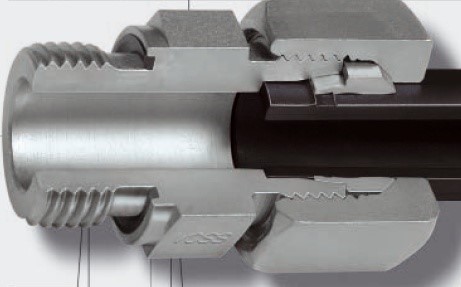

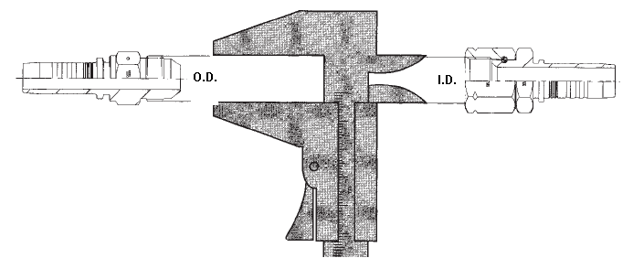

SAE J1453, O-RING FACE SEAL - ORFS Hydraulic Fitting

This type of connection is one of the Standards that provides reliable leakage control in hydraulic circuit applications and is designed to operate at high pressures.

The male has a straight tooth and an o-ring on the forehead, the female has a straight tooth and a straight face without o-rings. Sealing is achieved by pressing the o-ring of the male against the flat face of the female. In such applications, considering the operating temperature, NBR or VITON, 90 Shore o-ring should be preferred.

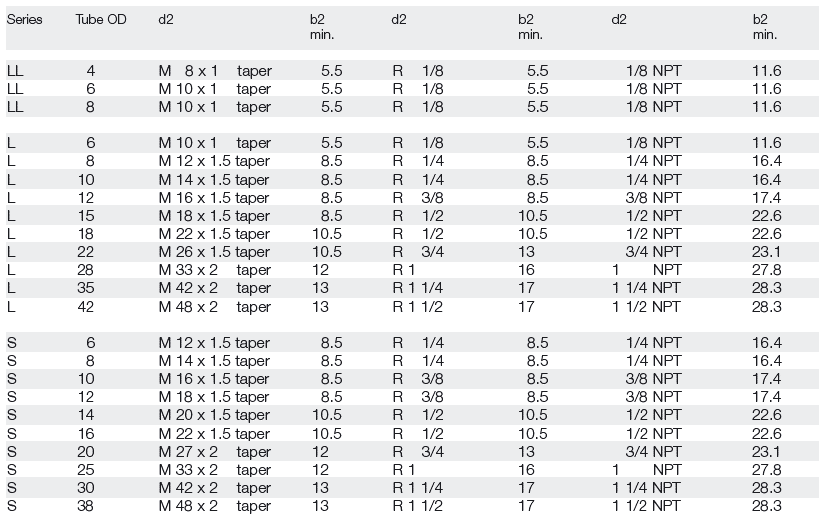

DIN 2353 METRIC Hydraulic fitting

The male has a 24 ° conical surface and is mechanically sealed with the same angle on the female part. Metric connections, which are the German connection type, are the most common connection type. It is rich in configurations compatible with different types of standards. Therefore, it is used more commonly than other connection types. It is preferred in many applications thanks to its ease of installation in pipe applications. (In ferrule type assemblies)

Metric type connections are widely used in steel drawn pipe connections especially used in hydraulic installations. Metric connection application types used in drawn steel pipes;

Connection Type with Ferrule System

Connection Type with SRC Ferrule System

Connection Type Made by Forming on SeideForm Pipe

Connection Type with Sdi-100 System

Flanged Type Connection Type Made with Sdi-300 System

Hydraulic Union Usage Areas

Hydraulic fittings are important components used to join, route or convert pipelines in hydraulic systems. Therefore, hydraulic couplings have a wide range of uses. Here are some areas where hydraulic fittings are commonly used:

1. **Building and Construction Machinery:** In construction machinery, hydraulic systems are generally used to transmit power and motion. Hydraulic fittings are commonly used on these machines to join pipelines and connect moving components.

2. **Automotive Industry:** It is found in many applications in the automotive industry, such as hydraulic systems, braking systems, steering systems and suspension systems. Hydraulic fittings are used to combine and connect pipelines in these systems.

3. **Agricultural Machinery:** Agricultural machinery is usually equipped with hydraulic systems. In these systems, hydraulic couplings are used to join and route pipelines for lifting mechanisms on tractors, tillage equipment, and other functions.

4. **Marine and Port Equipment:** In marine equipment and ports, hydraulic systems are often used to provide power and control. Hydraulic fittings are used to join and route pipelines on ships and port equipment.

5. **Industrial Machines:** Hydraulic systems in industrial machines are found in many different applications such as presses, injection molding machines, metal working machines. In these systems, hydraulic fittings are used to combine and connect pipelines.

6. **Aerospace Industry:** In the aerospace industry, hydraulic systems are found in many different systems in airplanes, helicopters, and spacecraft. Hydraulic fittings are used to join and direct pipelines in these systems.

Because hydraulic fittings are used in many different industries and applications, they are critical to the reliability and performance of systems. Therefore, the correct selection and installation of hydraulic fittings is of great importance.